LD-series

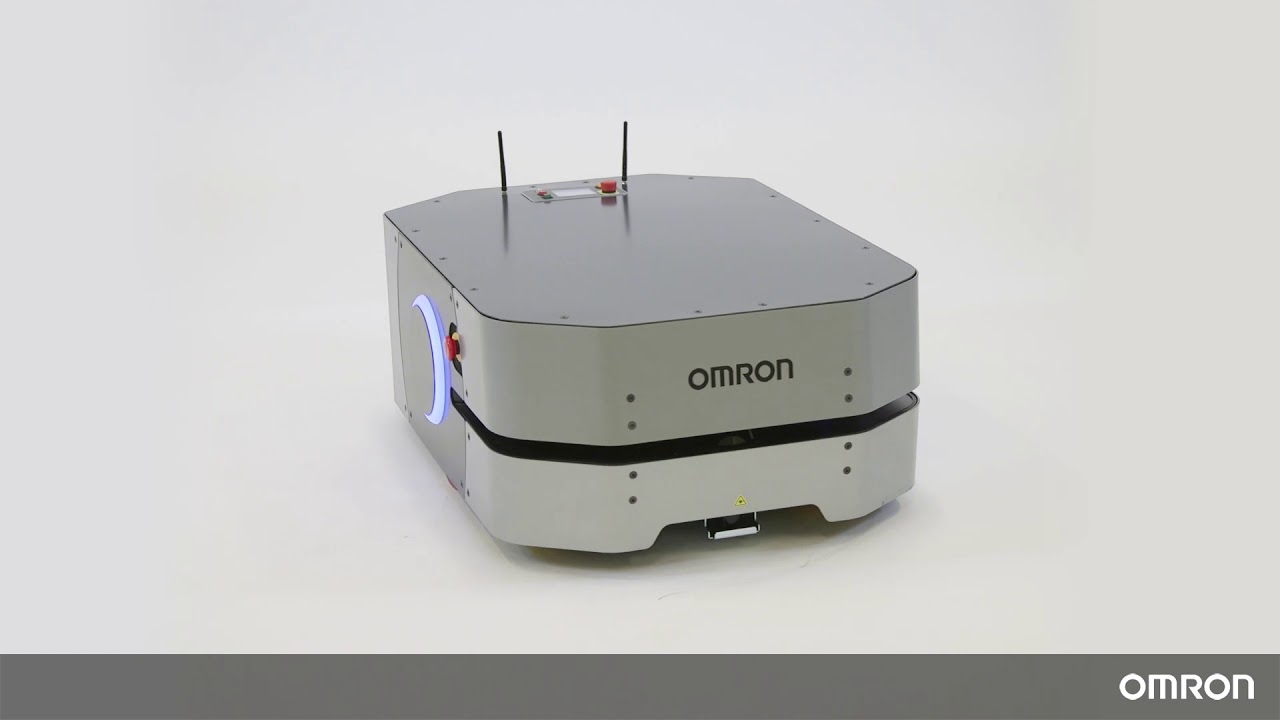

Robot mobili completamente autonomi

I robot mobili autonomi di OMRON sono progettati per migliorare in maniera significativa la produttività nelle attività di produzione e logistica. I nostri robot mobili consentono di aumentare la produttività, eliminare gli errori e migliorare la tracciabilità dei materiali, oltre a permettere ai dipendenti di concentrarsi sulle attività più complesse. Inoltre, a differenza degli AGV tradizionali, i nostri robot mobili "navigano" sfruttando le funzionalità normali dell'impianto, senza richiedere onerose modifiche.

-

Omron mobile robots

Omron's Autonomous Mobile Robots (AMRs): no facility modifications, no laser beacons, no floor magnets, no tapes and setup the robot within an hour.

01:49

Omron mobile robots

Omron's Autonomous Mobile Robots (AMRs): no facility modifications, no laser beacons, no floor magnets, no tapes and setup the robot within an hour.Robot mobile autonomo (AMR)

LD-series Mobile Robot Catalogo tecnico

Caratteristiche

Facile da montare

-

1Decisioni semplificate e costi ridottiOMRON fornisce un modello di abbonamento che offre costi iniziali ridotti, aggiornamenti continui e miglioramenti alla manutenzione delle funzioni. Il cliente può prendere decisioni più facilmente.

-

2App e topper selezionatiOMRON vanta diversi casi di successo riguardanti i topper; il dipartimento vendite OMRON può consigliare ai clienti le soluzioni migliori.

-

3Mappatura e definizione degli obiettiviDopo un breve tour nello stabilimento, il robot effettuerà una mappatura personalizzata e imposterà gli obiettivi di prelievo e rilascio.

-

4Semplicità d'usoIl semplice controllo tramite tablet e la semplice integrazione tra OMRON Fleet Manager e i sistemi MES e WMS consentono di utilizzare immediatamente i robot.

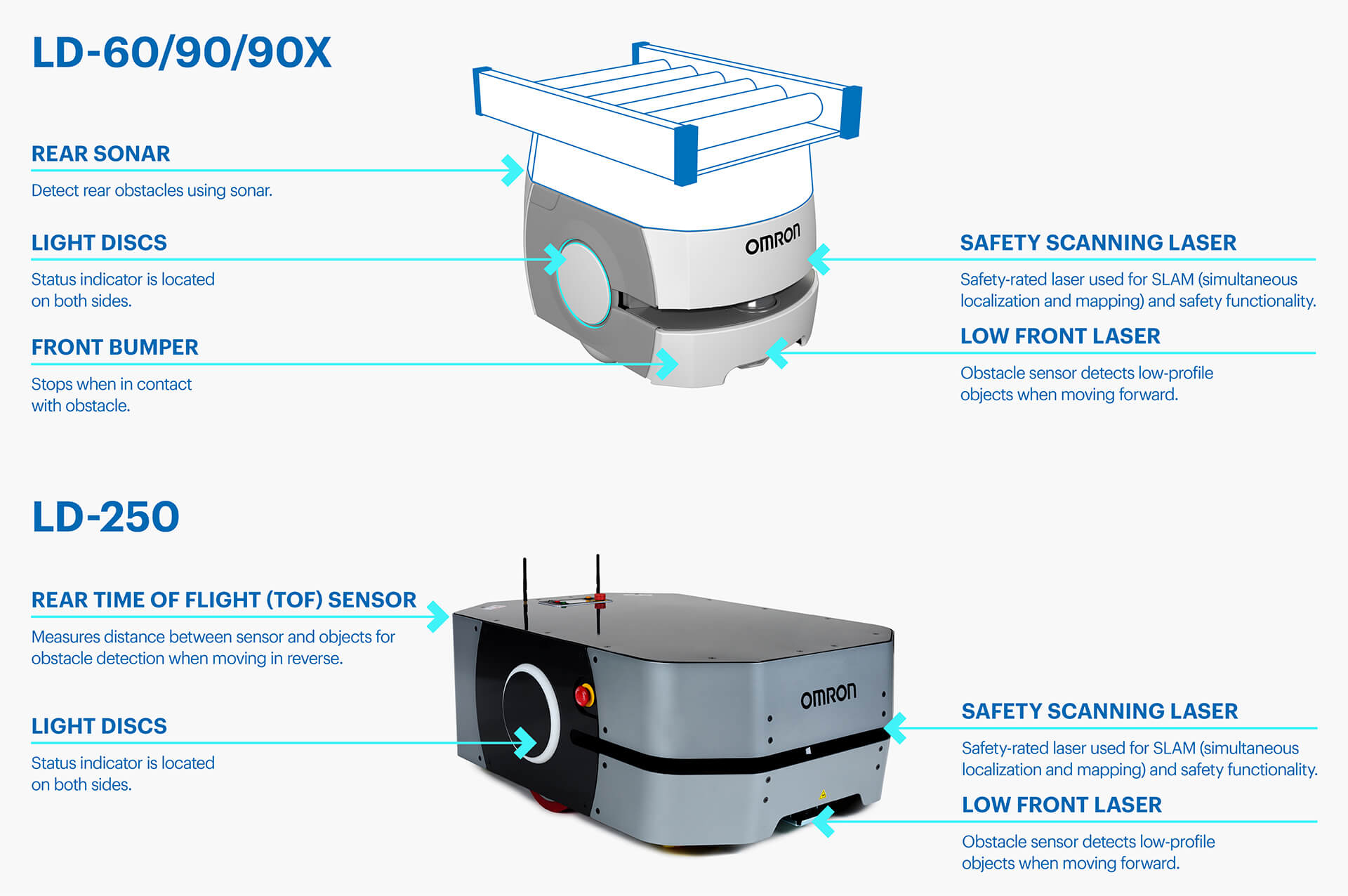

Sicurezza

Adatti per l'impiego in applicazioni di sicurezza, i nostri robot mobili utilizzano laser e sensori integrati per rilevare gli ostacoli nel proprio percorso e, in base alla velocità di movimento, attivano l'arresto di emergenza (E-stop) per prevenire le collisioni tra i veicoli e gli oggetti che incontrano durante il tragitto.

- Laser LIDAR

- Laser inferiore

- Laser laterale

- Paraurti anteriore

- Sonar

Funzioni di sicurezza

-

1Capacità di evitare ostacoli fissi e in movimento

-

2Facile aggiunta di arresti di emergenza

-

3Conformità agli standard di sicurezza ISO EN1525, JIS D6802 e ANSI B56.5

Tecnologia

Software e tecnologia AMR

I robot mobili autonomi (Autonomous Mobile Robot, AMR) di OMRON sono dotati di tecnologia AMR dedicata per la navigazione e il posizionamento dell'allineamento. Questa tecnologia consente agli AMR di muoversi in modo sicuro ed efficiente all'interno degli spazi di lavoro designati, anche in ambienti complessi. Gli AMR sono anche gestiti tramite software, il che li rende facili da usare e programmare.

- La tecnologia AMR dedicata utilizzata dagli AMR di OMRON include una varietà di sensori, come gli scanner laser, che consentono ai robot di mappare accuratamente l'ambiente e navigare in modo sicuro.

- Il software utilizzato per azionare gli AMR di OMRON è intuitivo, il che semplifica la programmazione dei robot per eseguire attività specifiche.

Navigazione affidabile

-

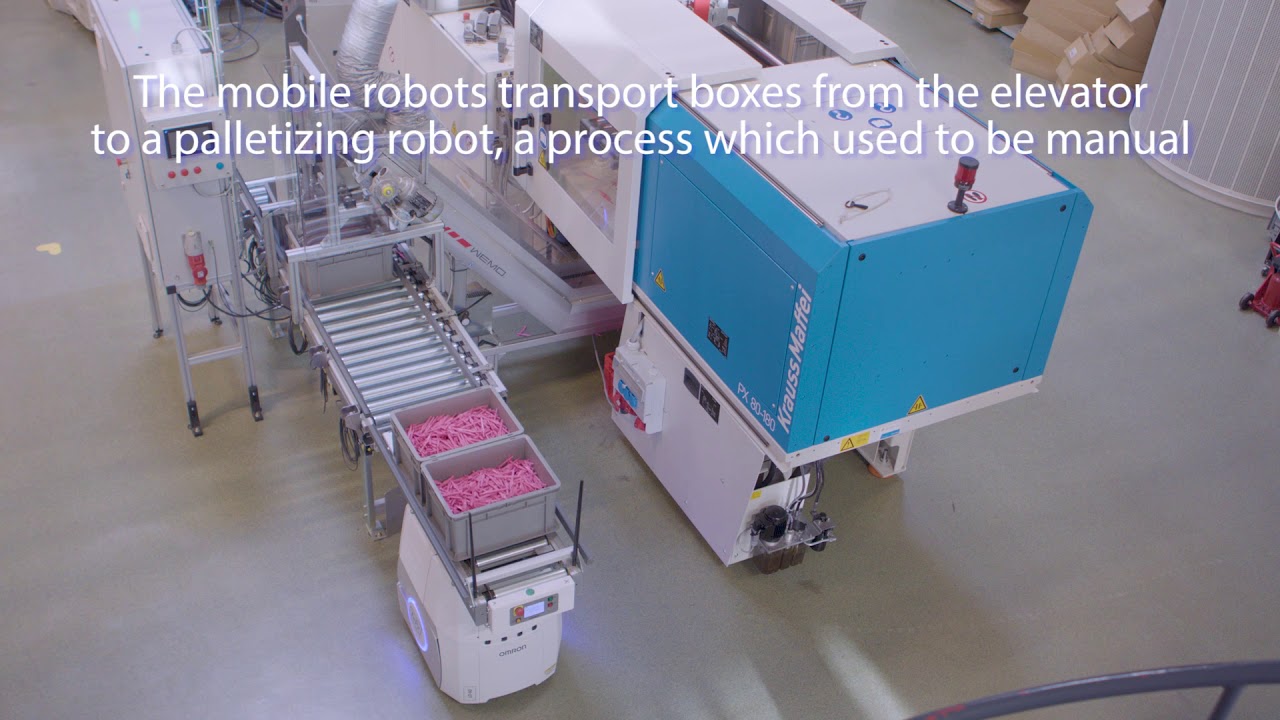

Omron's LD mobile robots automate material transport and increase efficiency - full version

Handling high-mix and low volume production, whilst compensating labour shortage are challenges for Omron manufacturing in Japan. See how LD mobile robots are used to automate material transport and increase efficiency, to accelerate human-machine collaboration.

03:47

Mobile robots smarten up Toyota’s new parts centre

Modelli

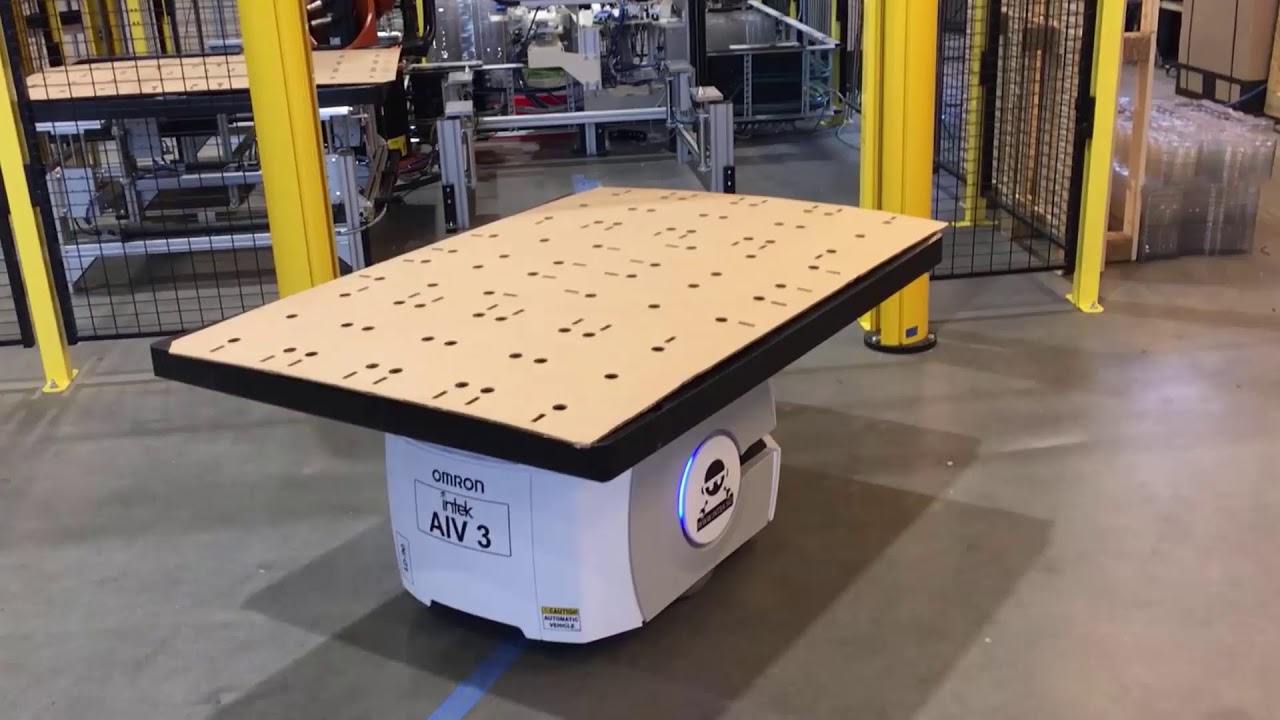

Piattaforme LD-60, LD-90 e LD-90x

La nostra piattaforma OEM mobile è a disposizione degli sviluppatori per la progettazione di applicazioni e portate personalizzate. La piattaforma comprende il nostro software di navigazione automatica proprietario, ideale per l'impiego negli ambienti affollati, nei corridoi stretti e nelle applicazioni che traggono vantaggio dall'uso di veicoli compatti e automatizzati. I nostri partner e sviluppatori OEM possono accedere facilmente a un sistema di azionamento affidabile, a un alimentatore integrato, alla ricarica automatica e all'I/O per l'integrazione dell'hardware per la portata nella piattaforma mobile.

La nostra piattaforma OEM mobile è disponibile in tre configurazioni, entrambe con un'opportunità di esecuzione fino a 19 ore al giorno:

- LD60, in grado di trasportare fino a 60 kg (velocità massima 1,8 m/s)

- LD90, in grado di trasportare fino a 90 kg (velocità massima 1,35 m/s)

- LD-90x, utilizzo in una configurazione Cart Transporter per aumentare il carico massimo fino a 170 kg (velocità massima 0,9 m.s)

Piattaforma LD-250

- LD-250, in grado di trasportare fino a 250 kg (velocità massima 1,2 m/s)

LD-250 Pieghevole

Piattaforme ESD LD-60/90/90x/250

I robot ESD sono progettati per ambienti di produzione complessi e consentono di espandere le applicazioni di movimentazione dei materiali automatizzata mantenendo la protezione. Progettati per fornire protezione ai prodotti sensibili alle scariche elettrostatiche (ESDS).

I rivestimenti ESD creano uno schermo protettivo intorno al robot che non solo protegge l'investimento, ma dissipa anche l'energia statica a terra in tutta sicurezza. Con i robot mobili ESD serie LD-250, forniamo una soluzione sicura per la movimentazione di componenti sensibili all'elettricità statica.

- Protezione dei giunti per i prodotti sensibili alle scariche elettrostatiche (ESDS) e per la serie LD.

- Conformità a IEC 61340-5-1 come superfici statiche controllate con Rg < 1 x 10^9.

- Protezione per intensità di campo superiori a circa 40 kV/cm d'aria.

- Skin progettate per resistere all'accumulo statico.

LD-250 ESD Pieghevole

Caratteristiche ed info per ordinare

| Prodotto | Mobile robot type | Maximum load | Maximum speed | Kit type | ESD protection | Battery included | Descrizione | |

|---|---|---|---|---|---|---|---|---|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot | No | No | Robot mobile, LD-60, senza Batteria |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + docking kit | No | No | Kit docking station per robot mobile, LD-60, caricabatterie, senza batteria |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + starter kit | No | No | AMR, LD-60, payload 60kg, velocità max 1800mm/s, inclusa docking station, top plate e joystick. Esclusa batteria |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot | Yes | No | Robot mobile, LD-60, ESD, senza Batteria |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + docking kit | Yes | No | Kit Docking Station per Robot Mobili, LD-60, ESD, Caricabatterie, senza Batteria |

|

|

|

OEM robot | 60 kg | 1.8 m/s | Mobile robot + starter kit | Yes | No | Starter Kit per Robot Mobili, LD-60, ESD, senza Batteria, con Caricabatterie, Joystick, Piastra Superiore |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot | No | No | Robot mobile, LD-90, senza batteria |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + docking kit | No | No | Kit docking station per robot mobile, LD-90, caricabatterie, senza batteria |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + starter kit | No | No | Starter kit robot mobile, LD-90, con caricabatteria, senza batteria, joystick, piastra superiore |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot | Yes | No | Robot mobile, LD-90, ESD, senza Batteria |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + docking kit | Yes | No | Kit Docking Station per Robot Mobile, LD-90, ESD, Caricabatterie, senza Batteria |

|

|

|

OEM robot | 90 kg | 1.35 m/s | Mobile robot + starter kit | Yes | No | Starter Kit per Robot Mobili, LD-90, ESD, senza Batteria, con Caricabatterie, Joystick, Piastra Superiore |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot | No | No | Robot mobile, LD-90x, senza batteria |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + docking kit | No | No | Kit docking station per robot mobile, LD-90x, caricabatterie, senza batteria |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + starter kit | No | No | Mobile Robot Starter Kit, LD-90x, con caricatore, senza batteria, joystick, piastra superiore |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot | Yes | No | Robot mobile, LD-90x, ESD, senza batteria |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + docking kit | Yes | No | Kit Docking Station per Robot Mobile, LD-90x, ESD, caricabatterie, senza batteria |

|

|

|

OEM robot | 90 kg | 0.9 m/s | Mobile robot + starter kit | Yes | No | Mobile Robot Starter Kit, LD-90x, ESD, senza batteria, con caricatore, joystick, piastra superiore |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot | No | No | AMR, LD-250, payload 250kg, velocità max 1200mm/s, esclusa docking station, top plate, joystick e batteria |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + docking kit | No | No | AMR, LD-250, payload 250kg, velocità max 1200mm/s, inclusa docking station. Esclusa batteria |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + starter kit | No | No | AMR, LD-250, payload 250kg, velocità max 1200mm/s, inclusa docking station, top plate e joystick. Esclusa batteria |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot | Yes | No | Robot mobile, LD-250, ESD, senza Batteria |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + docking kit | Yes | No | Kit Docking Station per Robot Mobili, LD-250, ESD, Caricabatterie, senza Batteria |

|

|

|

OEM robot | 250 kg | 1.2 m/s | Mobile robot + starter kit | Yes | No | Starter Kit per Robot Mobili, LD-250, ESD, con Caricabatterie, senza Batteria, Joystick, Piastra Superiore |

|

Accessori

Filtra per

Basic Gate NORD

Nord Modules

Evy-Box

Meanwhile

Modulo superiore LCP AMR per OMRON LD-250

Interroll

Modulo superiore LCP AMR per OMRON LD-60/90

Interroll

NORD P&D On-The-Fly Gate

Nord Modules

NORD QM200-OMRON

Nord Modules

NORD QM35 + 65 - OMRON

Nord Modules

NORD Wheel Gate

Nord Modules

Successivo

Siamo a tua disposizione

Hai domande? I nostri specialisti sono pronti ad assisterti in ogni fase del percorso.

Contattaci LD-series

ATTENZIONE! Non utilizzare questo modulo di contatto per i prodotti medicali Omron, per i quali vi invitiamo a consultare il sito Corman alla sezione Assistenza Tecnica.

Grazie per averci sottoposto la tua richiesta. Ti risponderemo non appena possibile.

Purtroppo abbiamo problemi tecnici. Il tuo modulo non è stato ricevuto correttamente. Ci scusiamo per l'inconveniete e ti chiediamo per favore di riprovare più tardi.

DownloadPreventivo per LD-series

Tramite questo modulo può richiedere un'offerta relativa al prodotto prescelto. Completi, per favore, i campi contrassegnati con *. I suoi dati personali verranno trattati secondo le normative vigenti. Le ricordo che il minimo importo fatturabile è di 400 € a cui bisogna aggiungere 25 € di spese amministrative.

Grazie per averci richiesto un'offerta. Vi risponderemo non appena possibile.

Purtroppo abbiamo problemi tecnici. Il tuo modulo non è stato ricevuto correttamente. Ci scusiamo per l'inconveniete e ti chiediamo per favore di riprovare più tardi.

DownloadSoluzioni

Soluzioni MoMa OMRON

Casi dei clienti

-

Mobile robots streamline internal logistics at HIPRA

Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport. HIPRA, a pioneering biotechnological company in the pharmaceutical industry, has transformed its internal logistics processes by installing a fleet of mobile robots supplied by OMRON. Read more:

03:30

Mobile robots streamline internal logistics at HIPRA

Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport. HIPRA, a pioneering biotechnological company in the pharmaceutical industry, has transformed its internal logistics processes by installing a fleet of mobile robots supplied by OMRON. Read more:

-

Operators and robots work in harmony: Grupo Antolin automates handling of car interior components

Major trends in the automotive industry – including an increasing emphasis on issues such as electrification, digitalization, and sustainability – are also driving changes in vehicle interiors. One of the largest international players in this sector is Grupo Antolin. As a key player at global automotive supply chain and high value manufacturing leader, the strategy of the company, Adv. Manufacturing 4.0, looks into integration of digital technology in the operations. One of the focus areas is the reduction and optimization of movements in internal logistic. Introducing autonomous mobile robots (AMRs) and collaborative robots (cobots), manufactured and supplied by OMRON, helps achieve a modernized and more sustainable factory where people and machines are working in harmony. For more information, visit:

03:11

Operators and robots work in harmony: Grupo Antolin automates handling of car interior components

Major trends in the automotive industry – including an increasing emphasis on issues such as electrification, digitalization, and sustainability – are also driving changes in vehicle interiors. One of the largest international players in this sector is Grupo Antolin. As a key player at global automotive supply chain and high value manufacturing leader, the strategy of the company, Adv. Manufacturing 4.0, looks into integration of digital technology in the operations. One of the focus areas is the reduction and optimization of movements in internal logistic. Introducing autonomous mobile robots (AMRs) and collaborative robots (cobots), manufactured and supplied by OMRON, helps achieve a modernized and more sustainable factory where people and machines are working in harmony. For more information, visit:

-

Mobile order preparation and operator support solution from Savoye with OMRON mobile robots

The Mobile Robot solution from Savoye is a flexible and economical alternative to manual processes. Mobile robots move autonomously, carrying packages and items to the various areas of the warehouse, allowing operators to be freed from: - Routes between launching area, picking areas and packaging areas - Fatigue generated by cart handling activities The operators remain in their picking area, thus devoting their time to value-added operations. The Savoye Mobile Robot solution can be used in stand-alone mode, independently interfaced with Savoye WMS and WCS software, or in addition to an automated system. There are many use cases, all relying on the same IT architecture: - Multi-package preparation (pick & pack), - Item picking before splitting (pick-then-pack) - Replenishment of retail picking locations For more information, please visit:

03:32

Mobile order preparation and operator support solution from Savoye with OMRON mobile robots

The Mobile Robot solution from Savoye is a flexible and economical alternative to manual processes. Mobile robots move autonomously, carrying packages and items to the various areas of the warehouse, allowing operators to be freed from: - Routes between launching area, picking areas and packaging areas - Fatigue generated by cart handling activities The operators remain in their picking area, thus devoting their time to value-added operations. The Savoye Mobile Robot solution can be used in stand-alone mode, independently interfaced with Savoye WMS and WCS software, or in addition to an automated system. There are many use cases, all relying on the same IT architecture: - Multi-package preparation (pick & pack), - Item picking before splitting (pick-then-pack) - Replenishment of retail picking locations For more information, please visit:

-

Material handling solutions with autonomous mobile robots

LCS has implemented applications with OMRON autonomous mobile robots in various markets and industries that require efficient, flexible and automated logistics. LCS Group has been operating on the Italian and European markets since 1989 as a System Integrator, offering complete, integrated and cutting-edge hardware and software solutions for internal logistics, airports and industrial automation. Music in this video Inspirational Corporate Ambient Artist: Aleksandr Shamaluev Album: Corporate Music Licensed to YouTube by HAAWK for a 3rd Party (on behalf of AShamaluevMusic); HAAWK Publishing, BMI - Broadcast Music Inc., and 3 music rights societies

02:36

Material handling solutions with autonomous mobile robots

LCS has implemented applications with OMRON autonomous mobile robots in various markets and industries that require efficient, flexible and automated logistics. LCS Group has been operating on the Italian and European markets since 1989 as a System Integrator, offering complete, integrated and cutting-edge hardware and software solutions for internal logistics, airports and industrial automation. Music in this video Inspirational Corporate Ambient Artist: Aleksandr Shamaluev Album: Corporate Music Licensed to YouTube by HAAWK for a 3rd Party (on behalf of AShamaluevMusic); HAAWK Publishing, BMI - Broadcast Music Inc., and 3 music rights societiesVideo

-

Mobile Manipulator combines a cobot arm with an autonomous mobile robot for flexible production

OMRON's autonomous mobile manipulator solution supports flexible manufacturing and improves efficiency by integrating a self-navigating LD mobile robot with OMRON's collaborative robot arm. What will you use it for?

01:43

Mobile Manipulator combines a cobot arm with an autonomous mobile robot for flexible production

OMRON's autonomous mobile manipulator solution supports flexible manufacturing and improves efficiency by integrating a self-navigating LD mobile robot with OMRON's collaborative robot arm. What will you use it for?

-

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobots

00:53

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobots

-

OMRON FLOW Core 3.0 Selectable Autonomy

Enables users to tailor traffic flow with powerful path modes, ranging from autonomous guided vehicle (AGV)—but without the costly infrastructure—to limited detour windows, to the pure flexibility of a traditional AMR. #omronindustrialautomation #mobilerobots

01:09

OMRON FLOW Core 3.0 Selectable Autonomy

Enables users to tailor traffic flow with powerful path modes, ranging from autonomous guided vehicle (AGV)—but without the costly infrastructure—to limited detour windows, to the pure flexibility of a traditional AMR. #omronindustrialautomation #mobilerobots

-

Omron Mobile Planner Tablet Edition - Intro

Introduction of the Omron Mobile Planner - an easy to use, portable, monitoring and control user interface tool for LD Mobile Robots.

03:21

Omron Mobile Planner Tablet Edition - Intro

Introduction of the Omron Mobile Planner - an easy to use, portable, monitoring and control user interface tool for LD Mobile Robots.Download

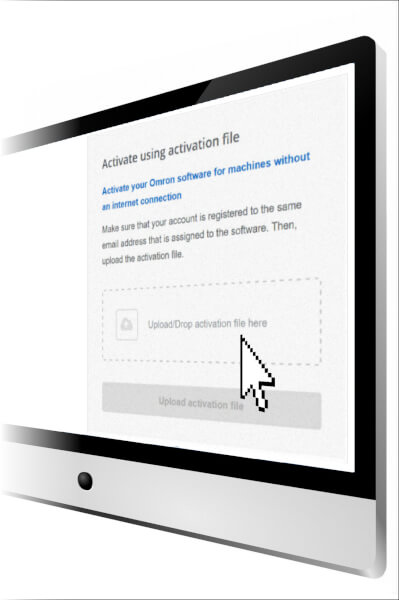

Attiva il software del tuo robot mobile

Hai bisogno di assistenza?

Siamo qui per aiutarti! Mettiti in contatto con noi e i nostri specialisti ti aiuteranno a trovare la soluzione migliore per la tua azienda.

Contattaci LD-series

ATTENZIONE! Non utilizzare questo modulo di contatto per i prodotti medicali Omron, per i quali vi invitiamo a consultare il sito Corman alla sezione Assistenza Tecnica.

Grazie per averci sottoposto la tua richiesta. Ti risponderemo non appena possibile.

Purtroppo abbiamo problemi tecnici. Il tuo modulo non è stato ricevuto correttamente. Ci scusiamo per l'inconveniete e ti chiediamo per favore di riprovare più tardi.

DownloadPreventivo per LD-series

Tramite questo modulo può richiedere un'offerta relativa al prodotto prescelto. Completi, per favore, i campi contrassegnati con *. I suoi dati personali verranno trattati secondo le normative vigenti. Le ricordo che il minimo importo fatturabile è di 400 € a cui bisogna aggiungere 25 € di spese amministrative.

Grazie per averci richiesto un'offerta. Vi risponderemo non appena possibile.

Purtroppo abbiamo problemi tecnici. Il tuo modulo non è stato ricevuto correttamente. Ci scusiamo per l'inconveniete e ti chiediamo per favore di riprovare più tardi.

Download

_reference_manual_en.jpg)

_leaflet_en.jpg)